~ Weight Indicators/Controllers ~

KM indicators complete the sensing systems. With KM indicators you can monitor from 1 to 120 vessels of level, weight or a combination thereof. The SVS™, STX™ and Weight II™ feature operator-selectable speeds and resolutions. The MVS™ is designed to custom-configure your system with off-the-shelf input and output requirements, for the right system you need today, and the ability to easily expand in the future.

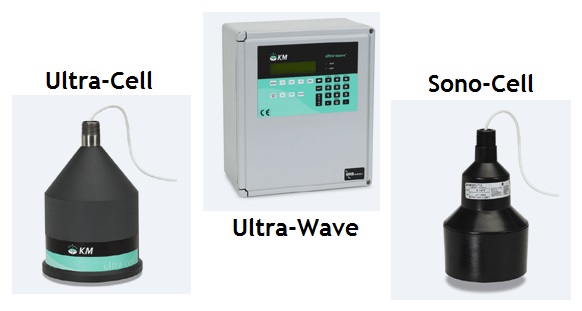

Non-contact ultrasonic level measuring system provides continuous measurement and monitoring of levels in multiple vessels containing powders, solids, liquids and slurries. Non-contract means no contamination of material and no lost parts or cables. Its modular design allows easy configuration for a number of sensors, relays, point level inputs, current loops, and PLC interfaces.

Provides a reliable means of gathering and transmitting real-time inventory information from anywhere, anytime via your LAN or the Internet. Also makes it possible for suppliers to manage their customers inventories more effectively than ever before. The result is a fully functional remote Vendor Managed Inventory (VMI) process by which a supplier keeps track of a customer’s inventory, scheduling deliveries according to known thresholds and reducing the high cost of data collection, personnel and equipment, measurement errors, and overstocking for both supplier and customer. Suppliers make fewer delivery runs and eliminate wasteful haul-backs or split-loads, while customers minimize inventory, reduce lead-time, and eliminate run-outs.

~ Load Cells/Direct Support Sensors ~

Designed for high accuracy applications, KM load cells are ideal for applications ranging from sanitary SIP/CIP conditions to rugged outdoor environments. KM load cells deliver reliable, repeatable measurements for your varied operating conditions and applications, from 50 to 1,000,000 lb. capacities. Secured to your tank, KM has your safe, direct support weighing solution.

~ Interfaces ~

Analog and digital interfaces are modular and available for single and multi-point indicators/controllers giving you the ability to connect KM signal processors directly to your Allen-Bradley Remote I/O Network, Modbus or Siemens Profibus. Weight/level information is input in digital form, eliminating the need for special software with the flexibility of communicating with a variety of factory busses. Wiring costs are significantly decreased. Indicators and controls are offered with different communications options. Consult factory.

Turn your existing Tank/Vessel/Structure into a scale. KM pioneered the popular bolt-on, strain gauge, sensor technology for continuous measuring of vessel weight. Bolt-on sensors measure the stress level changes in vessel supports caused by material movement and therefore are not fooled by side build-up, angles of repose or air pockets. Quickly and easily installed, this non-intrusive, cost-effective method is an excellent alternative to traditional level sensing.

** Click here for Kistler-Morse Application Data Sheets **